Chelating resins are types of cross linked functional polymer material which can be formed by polydenate chelate complex with metal ions. Compared to ion exchange resins, chelating resins have stronger bonding forces to link with metal ions with high selectivity. It can be used to separate and recycle metal ions into various fields such as amine acid separation, hydrometallurgy and the prevention of pollutants into the waste stream.

Characterics of TRN’s Chelating resins:

- Strong resistance to penetration and shock

- High volumetric chelating capacity

- Uniform particle size for excellent regeneration operation

Chelating resins for membrane caustic soda:

To increase the effective and prolong the life of membranes, membrane caustic soda requires highly purified brine water. However, traditional depositing techniques can hardly meet this requirement. Our products LSC-500 and LSC-100 (amino carboxylic acid chelating resins) are able to effectively remove harmful ions like Ca2+, Mg2+, Sr2+, therefore making secondary brine water satisfy the requirements for membrane technology.

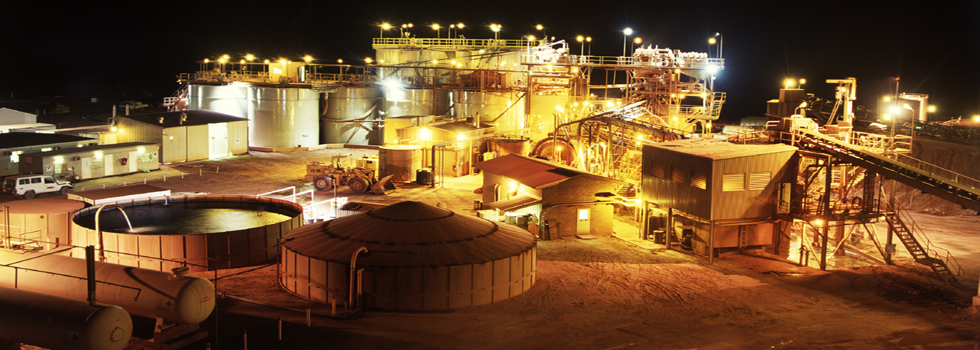

Other application:

- Separation, enrichment of noble metals Au, Pt, Pd, etc.

- Mercury removal

- Boron removal

- Selective adsorption of bivalent metallic ions.

- Removal of Copper, Nickel, Cobalt, and platinum group metals

- Gold Recovery

- Selective heavy metal removal from waste streams

Characterics of TRN’s Chelating resins:

- Strong resistance to penetration and shock

- High volumetric chelating capacity

- Uniform particle size for excellent regeneration operation

- Applied by companies worldwide